Building with Wood: Environmental and Economic Potential - Analysis n°211

Partager la page

Wood based construction, primarily promoted for ecological reasons, represents a structuring market for the French forest-wood sector. This note provides an overview of the major challenges and key trends in this area, which is experiencing a strong wave of innovation (e.g., materials, construction techniques). Despite mastered processes and promising economic perspectives, societal perceptions and difficulties in mobilizing the resource remain major obstacles. The experiences of other EU countries, particularly in Scandinavia, may offer valuable examples.

Download

Introduction

Wood is suitable for construction due to its load-bearing (e.g., strength, flexibility) and insulating properties (low thermal conductivity). Used since Antiquity, it was widely employed during the Middle Ages to build cities (e.g., timber-framed houses). The evolution of regulations, competition from modern materials resistant to compression and fire and capable of spanning large distances (e.g., concrete, steel), and the emergence of industrial logic led to its decline by the end of the 19th century. While the wood construction sector became industrialized early in the U.S. and Scandinavia, post-WWII reconstruction policies in France favored concrete, relegating wood to experimental projects.1

Today, wood is promoted by public policies for environmental reasons but also as a way to valorize local resources and territories.2 Technological advances in recent decades now enable ambitious projects, including high-rise buildings.

This note first analyzes the two major strengths of wood construction: its environmental benefits and technical characteristics. It then examines the sector’s market potential and public perception of the material. Finally, three prospective scenarios are presented for the use of wood in the construction sector in France by 2050.

The Promise of Environmental and Technical Performance

A biological resource contributing to climate change mitigation

Wood construction is a lever to improve France’s carbon balance. Trees sequester carbon throughout their growth, at about 1 ton of CO2 equivalent (tCO2eq) per cubic meter of fresh wood. This carbon remains stored in wood-based products throughout their lifetime, which may range from decades to a century (e.g., a 50-year half-life for a timber frame). This helps prevent the release of forest-stored carbon, for example during wildfires. Using wood in place of more emission-intensive materials also avoids greenhouse gas emissions. In construction, wood’s “substitution factors” (coefficients representing avoided emissions when replacing another material) generally indicate a climate benefit3 (figure 1).

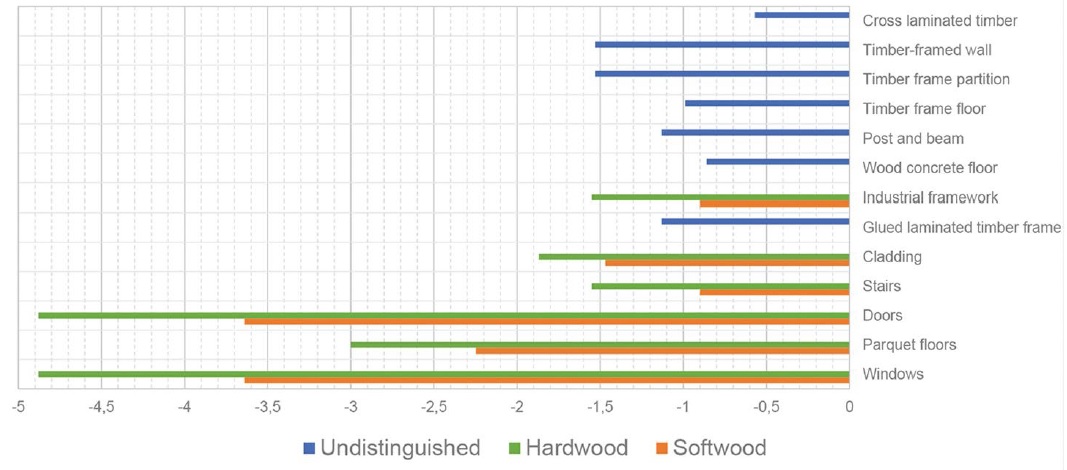

Figure 1 – Substitution factors for various hardwood and softwood construction products (kgCO2/kg wood)

Graph showing the substitution coefficients in kgCO2/kg of wood for various timber construction products (e.g. glulam, windows).

Interpretation: Each value indicates the avoided emissions from using 1 kg of wood construction product, based on a life cycle analysis considering both production and end-of-life stages.

Source: Author, based on IGN & FCBA data, 2024

This potential, however, is variable. Substitution factors depend on the life cycle boundaries considered and the assumptions regarding forest growth. They are not static, as competing materials may decarbonize, and vary with the carbon intensity of the energy mix (e.g., country-level emissions-to-energy ratios). The carbon footprint and climate neutrality of wood depend on the type of resource used, forest regeneration conditions, and the methodologies and conventions employed for calculations.4 Building use and urban planning must also be considered, as housing type and density may be more powerful levers for decarbonization than material choice alone.5

Nonetheless, wood’s biological nature positions it within the broader “bioeconomy.” The environmental impacts of forest management (on water, soil, biodiversity, etc.) can be controlled if sustainability criteria such as those defined by the Forest Europe process are followed. In contrast, concrete and steel are produced from mineral resources whose extraction (e.g., sand) may damage ecosystems, consumes large volumes of water, and emits pollutants. Forests, by contrast, provide environmental amenities (ecosystem services) and other products (e.g., energy).

Technical innovations, both mature and emerging

Modern wood construction relies on technical and organizational innovations. It uses engineered wood products like solid panels and fiber-based insulation. Glued laminated timber and cross-laminated timber, composed of solid wood bonded with adhesives, overcome size limitations and natural weaknesses of wood. Advances in chemistry have enabled improved glues and treatments against fire, moisture, etc. Techniques such as wood framing rely on machining and pre-assembly of small parts, enabling quick construction with limited labor needs.

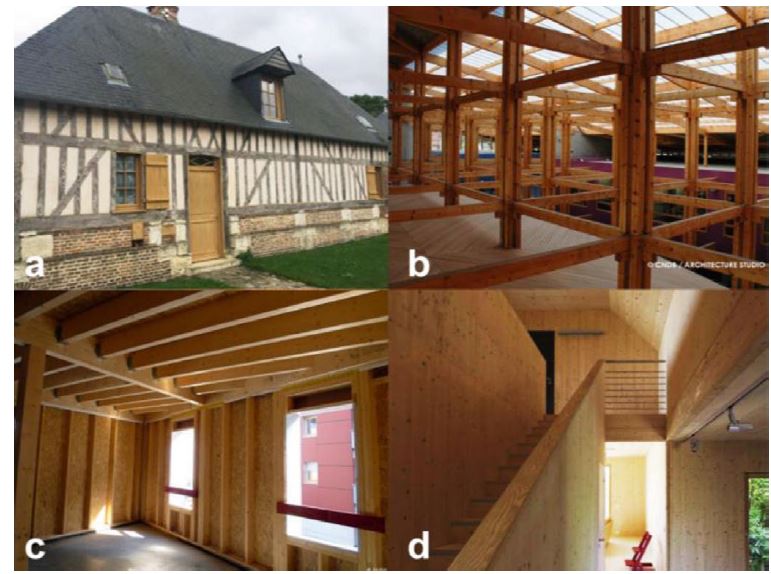

Several construction systems coexist on the market (figure 2). Wood framing, the most common in France, accounts for 85% of timber houses.6 This system of narrowly spaced sawed lumber and sheathing panels for lateral stability and insulation allows for quick construction of medium-sized buildings (typically 2-4 stories). The post-and-beam system uses widely spaced structural elements of large cross-section. Though flexible, it is expensive and better suited to larger projects such as commercial buildings and multi-unit housing, where its market share is growing (16% in 2020, 23% in 2022). Solid panel construction, an emerging technique, remains less developed in France (13% of collective timber housing) compared to Germany or Austria.

Figure 2 – Types of timber construction systems. Historic timber-framed house (a), post-and-beam system (b), wood frame (c), cross-laminated solid panels (d)

Set of four photographs of timber construction systems: half-timbered, post-and-beam, timber-framed, solid laminated panels.

Source: DREAL Centre-Val de Loire (a), FCBA et CSTB (b, c et d)

Wood construction is expected to continue benefiting from significant innovation. Hybrid construction, combining wood with complementary materials, is growing.7 A building may pair a concrete structural frame (fire resistance, thermal inertia) with wood panels for the envelope (insulation, aesthetics, lightness). Wood can also be part of composites: some concretes replace 10-20% of cement with wood ash.8 Off-site prefabrication of modules and on-site assembly, supported by digital technologies, enable rapid, flexible design and construction. It is also possible to functionalize components at the factory: “smart” panels can integrate connectivity elements (IT, electrical) during manufacturing.9

A Promising Market for the Forest-wood Sector

A rather growing construction market

In 2022, the construction market represented 49% of the added value of the forest-wood sector and about half of its direct employment.6 That year, wood held a 6.2% market share in residential construction by volume, with higher penetration in single-family housing (7.3%) than multi-family (5.3%, often in mixed wood-concrete or wood-metal structures). The trend is upward in the latter (4.6% in 2020, 4.3% in 2018) but declining in single-family units (9.7% and 9.4%, respectively). Wood is more established in industrial/artisanal and agricultural buildings, with market shares of 23.5% and 27.3%, respectively, and for extension projects (28%), where it is growing. Renovation is another major segment (27% of total revenue). Opportunities exist for further expansion: two recent foresight studies estimate that demand for construction wood in France could increase by 29% to 49% between 2019 and 2050.10

Wood is more established in northern EU countries, particularly Sweden, where 90% of single-family homes and 20% of multi-family units use wood framing (figure 3). This success stems from early development of an integrated industry, post-war public support, and cultural norms. A more recent wave of success is driven by the promotion of construction systems (e.g., off-site prefabrication) rather than of the material alone.11

Figure 3 – Use of wood in new residential construction across countries

|

Country |

Wood volume |

Wood volume |

|

Sweden |

0.28 – 0.35 |

20.5 – 25.4 |

|

Austria |

0.17 – 0.22 |

17.1 – 21.1 |

|

Norway |

0.17 – 0.18 |

20.9 – 23.1 |

|

Switzerland |

0.15 – 0.16 |

15.0 – 16.5 |

|

Finland |

0.14 – 0.16 |

12.5 – 14.0 |

|

Germany |

0.11 – 0.18 |

11.4 – 18.7 |

|

France |

0.07 – 0.09 |

5.8 – 7.5 |

Table showing, for several European countries, the quantities of wood used in new buildings, by habitable surface area and on average per dwelling.

Source: Sikkema R. et al., 2023, “A market inventory of construction wood for residential building in Europe–in the light of the Green Deal and new circular economy ambitions”, Sustainable cities and society

In France, wood construction faces several challenges. Some are cyclical, slowing down the entire building sector (e.g., inflation, interest rate hikes). However, the sector appears dynamic: revenues are increasing and most businesses plan to expand capacity. Regulatory challenges include costs associated with fire safety standards. In the medium term, however, regulations should favor bio-based materials, as seen with the RE2020 environmental regulation, which incorporates life cycle requirements for new buildings (carbon footprint, material end-of-life).

Structural challenges nonetheless persist. The wood sector is fragmented, with many small companies, especially in primary processing.12,13 Sawmills in particular suffer from underinvestment, limiting their ability to produce high value-added products (e.g., cross-laminated timber). To address this, industry stakeholders are developing joint initiatives (e.g., France Bois 2024, Résobois, Bois de France). Additionally, construction relies heavily on softwoods, whose harvest in France has plateaued (14.4 million m3 per year on average between 2017 and 2023).14 This creates dependence on imported processed products and underutilization of domestic hardwood resources. Climate change and pathogen hazards are expected to increase salvage logging, which the sector must be equipped to valorize.15

Cost can also be a barrier. A study of 19 housing projects in the Paris region estimated an average cost of €1,972 per m2 of living space, 11% more than for concrete projects.16 Costs vary widely and are not necessarily correlated with environmental performance, which generally exceeds current regulations (RE2020). A study in the Poitou-Charentes region found that wood construction for single-family homes cost 3.1% more than concrete block options, but that this difference could disappear or reverse depending on assumptions.17 Costs thus depend on calculation parameters, regulatory requirements, raw material prices, etc.

Shifting perceptions of wood construction

In the construction sector, concrete remains the norm. Nonetheless, several surveys reveal a positive image of wood among consumers, especially where it has long been promoted (Sweden, Germany), for environmental, aesthetic, and comfort reasons.18 Concerns persist around its long-term durability, fire resistance, and sustainable forest management. A communication strategy addressing prejudices against wood, product traceability, and sustainability certification could complement current messaging, focused on technical and climate benefits. These factors must however be viewed in a broader context, where location and price also drive buyers’ choices.

The State can help shape perceptions, notably through public procurement. Experimental housing projects launched in 1978 helped establish wood as a credible material alongside concrete, particularly through multi-family pilot projects1. Public procurement can support major emblematic projects, such as the Paris 2024 Olympics. Collaboration between Solideo (the Olympic delivery authority) and industry stakeholders via France Bois 2024 helped overcome technical hurdles (prefabrication, fire resistance, etc.) for major buildings (e.g., athletes’ village, temporary Grand Palais, concave frame of the aquatic center), while also familiarizing decision-makers and citizens with low-carbon wood construction. Smaller projects exist too, such as schools (e.g., Vincent Auriol nursery school, 2019; Maurice Utrillo middle school, 2020, both in Paris).19

At the local level, municipalities act as catalysts between demand, industry, and resources. Swedish cities are recognized for green investment, pilot project funding, and zoning policies. In France, many local authorities have committed to using wood via “wood-bio-based pacts.” By 2030, the French Environmental Code requires that bio-based and low-carbon materials (including wood) be used in 25% of public construction and renovation. Labels and other collective projects address various topics such as traceability, know-how recognition, and short supply chains (Bois des Alpes, Bois de France, AOP, Terres de Hêtre, etc.). Territorial forest charters, often led by inter-municipalities or regional hubs, promote local resources. Both tools help make the territory a strategic asset.20 Lastly, calls for expressions of interest and competitions increase visibility among industry players and architects (e.g., France 2030 project calls, national wood construction award).

Building with Wood by 2050: Three Scenarios

The scenarios that follow imagine different ways in which timber construction will develop in the future. These hypothetical forecasts deliberately explore contrasting trajectories. They do not claim to describe reality in advance, nor what it should be, but are an invitation to reflect.

A high-end niche in a prolonged crisis

In this scenario, the building sector remains in crisis. Raw material and energy prices rise, interest rate hikes constrain financing, and new work patterns (remote working, flexible offices) reduce demand for commercial real estate. Political and trade tensions persist globally, and inequality increases in France.

As a result, wood construction remains costly, and project numbers decline, delaying ecological transition goals. This contraction limits the sector’s incentive to structure and invest in high value-added technologies. Mass adoption of wood construction, a driver of cost reduction, does not happen.

However, strong trends in technical innovation continue, leading to new products (e.g., smart panels) for increasingly ambitious structures. With ecological transition still a priority, major public and private stakeholders maintain their environmental goals. Even without mass demand, iconic wood construction projects multiply, driven by the State and large corporations as part of their CSR policies. This is reinforced by growing interest from architects.

Wood construction becomes a high-end niche, offering a premium outlet for part of the French forest-wood sector and valorizing high-quality resources. Though small, this visible market provides a showcase, helping structure the wood construction industry and build brand identity. Meanwhile, the concrete industry, through lobbying and greener practices (e.g., recycling, wood-concrete blends, low-carbon cement), maintains dominance. Wood remains marginal to the mainstream model, which changes little.

Ecological planning drives moderate success

Despite cyclical difficulties, wood construction proves resilient and gains market shares thanks to state and industry actions. Stakeholders ramp up technical support, standardization, and promotion efforts.

Wood residential construction increases, reaching the 20% market share seen in Austria and Germany. Wood dominates in segments where it is already strong (non-residential, renovation, extensions) and becomes the norm for temporary buildings. Concrete retreats from these market segments but remains dominant in residential construction. However, the upstream wood sector still faces structural issues: fragmented private ownership, underinvestment in processing, etc. Calls for forest management and upstream-downstream integration continue.21

Climate change intensifies natural disturbances and diebacks, making it difficult to balance supply and demand for biomass. Wood industries from Scandinavia and North America, integrated and competitive, retain their lead while their resources remain less affected.22 Current and upcoming plantation programs (e.g., China, India, Brazil, Chile) increase wood and processed product availability outside Europe. Facing growing demand and weakened local resources, French wood construction remains import-dependent.

Wood at the heart of a territorial bioeconomy

A strong bioeconomy policy focused on bio-based materials and closed material/energy loops emerges. Centered on industrial innovation and biotechnologies, it channels investment into the downstream wood sector, including traditional industries and emerging wood startups.23

This bioeconomy is territorially rooted, with local governments as catalysts. Industrial clusters adopt industrial ecology principles to optimize material and energy flows, and valorize local resources.24 Wood construction expands through project calls, demonstrators, etc., while the sector restructures locally around diverse markets: energy, chemicals, etc.

Local industry encourages upstream development tools (e.g., forest management groups, supply contracts) to address fragmentation. These dynamics coincide with heightened environmental awareness and more flexible lifestyles (e.g., remote work, digital nomadism), enabling citizens to reinvest in economically revitalized rural areas.

However, the sustainability of biomass supply may become challenging due to worsening climate impacts. More intensive forest management could affect environmental amenities. Local conflicts already seen today multiply, requiring trade-offs between wood uses and forest functions.25 Development may also be uneven, with some areas left behind due to poor or fragilized resources, or lack of industrial interest.

Conclusion

Wood construction offers climate mitigation benefits and performance comparable to conventional materials. Consolidating this outlet is a competitiveness issue for the French forest-wood sector.

Despite its positive image, wood faces cyclical (e.g., building sector difficulties), structural (e.g., sector fragmentation, resource mobilization), and behavioral (e.g., misconceptions) challenges. As ecological planning advances, wood construction should continue to develop. However, it must be integrated with other mitigation solutions in the building sector (urban planning, consumption habits, sobriety, etc.) and considered in relation to other wood uses (e.g., energy, chemicals) and forest functions (e.g., ecosystem services, biodiversity).

The forest is ultimately a social entity. Downstream market evolution leads to upstream management changes, which may face resistance or generate conflict. Sustainable forest management, in France and abroad, is a key public concern. In this context of deep change, a systemic approach to the seemingly sectoral issue of wood construction is necessary.

Miguel Rivière, Centre for studies and strategic foresight

1. Berthier S., 2017, Création architecturale et industrialisation de la filière bois : l’architecture comme milieu d’expérimentation des innovations techniques, thèse de doctorat, université Paris-Saclay.

2. Ex. Conseil National de l’Industrie, 2024, Contrat stratégique de la filière bois 2023-2026 et Secrétariat général à la planification écologique, 2023, La planification écologique pour la forêt : principaux enjeux et leviers.

3. Leskinen P. et al., 2018, “Substitution effects of wood-based products in climate change mitigation”, Science to Policy, 7, European Forest Institute.

4. Meyer, F. et al., 2024, “The carbon footprint of future engineered wood construction in Montreal”, Environ. Res.: Infrastructure and Sustainability.

5. Peuportier B., 2022, Note sur l’analyse du cycle de vie des matériaux biosourcés, lab recherche environnement Vinci ParisTech.

6. France Bois Forêt & CODIFAB, 2023, Enquête nationale de la construction bois : activité 2022.

7. CODIFAB, Union industriels constructeurs bois, Fédération française du bâtiment, 2021, Mixité : Solutions constructives de demain.

8. Teker Ercan E.E. et al., 2023, “Wood Ash as Sustainable Alternative Raw Material for the Production of Concrete. A Review”, Materials.

9. Horx-Strathern O., Varga C. and Guntschnig G., 2017, “The Future of Timber Construction: CLT–Cross Laminated Timber. A study about changes, trends and technologies of tomorrow”, Zukunftsinstitut Österreich GmbH.

10. IGN, FCBA, 2024, Projections des disponibilités en bois et des stocks et flux de carbone du secteur forestier français ; Carbone 4, 2023, Scénario de convergence de filière. Résumé exécutif.

11. Schauerte T., 2010, “Wooden house construction in Scandinavia–a model for Europe”, Internationales Holzbau-Forum (IHF 2010): Aus der Praxis–Für die Praxis; Le Pierrès O., Grimault J. and Bellassen V., 2023, Développer les usages du bois à longue durée de vie : regard sur les filières allemande, roumaine et suédoise, I4CE.

12. Cour des comptes, 2020, La structuration de la filière forêt-bois, ses performances économiques et environnementales, Communication à la commission des finances, de l’économie générale et du contrôle budgétaire de l’Assemblée nationale.

13. Gaudé, L., Sémécurbe F., 2024, Les scieries : des productions spécialisées avec des modèles économiques spécifiques, Agreste Primeur n° 6.

14. Agreste, 2025, Récolte de bois et production de sciages en 2023, Chiffres et données.

15. Froissart P., 2024, Baisse de la récolte après une année record, Agreste Bourgogne-Franche-Comté Études, n° 80.

16. Barnhusen F. et al., 2024, “Le bois devient-il compétitif sur le marché francilien de la construction ?”, Note rapide de l’institut Paris région.

17. Futurobois, 2015, Comparatif des prix de la construction individuelle en Poitou-Charentes, rapport pour la DREAL Poitou-Charentes.

18. Viholainen N. et al., 2021, “Citizen views on wood as a construction material: results from seven European countries”, Canadian Journal of Forest Research.

19. See the interactive map of wood construction projects developed by FiBois Ile-de-France.

20. Lenglet J., 2018, “Réorganisation institutionnelle et recomposition territoriale de la filière forêt-bois française : exemples du Grand-Est et de la Franche-Comté”, Annales de géographie.

21. Vinçon P. et al., 2024, Mise en gestion durable de la forêt française privée, Rapport interministériel IGF, CGAAER et IGEDD.

22. Schelhaas, Mart-Jan, et al., 2015, “Alternative forest management strategies to account for climate change-induced productivity and species suitability changes in Europe”, Regional Environmental Change.

23. Xylofutur, 2024, Feuille de route pour une French Woodtech.

24. Industrial ecology is an approach aimed at limiting the impact of industry on the environment, inspired by the cyclical functioning of ecosystems. Among other things, it is based on: optimising the spatial location of industries, making the most of co-products between several facilities, pooling certain practices, etc.

25. Nousiainen, D. and Mola-Yudego, B., 2022, “Characteristics and emerging patterns of forest conflicts in Europe-What can they tell us?”, Forest Policy and Economics.

Voir aussi

Modélisation prospective et action publique dans le secteur forêt‑bois - Analyse n°204

11 juillet 2024Prospective

Rapport d'études "La scierie de feuillus du futur. Quels choix stratégiques pour demain ?

14 novembre 2019Enseignement & recherche

Leviers forestiers en termes d’atténuation pour lutter contre le changement climatique aux horizons 2020, 2030, 2050

08 septembre 2016Enseignement & recherche

Évaluation du volet « mobilisation des bois chablis » du plan de solidarité nationale consécutif à la tempête Klaus - Analyse n°70

08 juillet 2014Production & filières